Image: CDC/Unsplash

Image: CDC/Unsplash

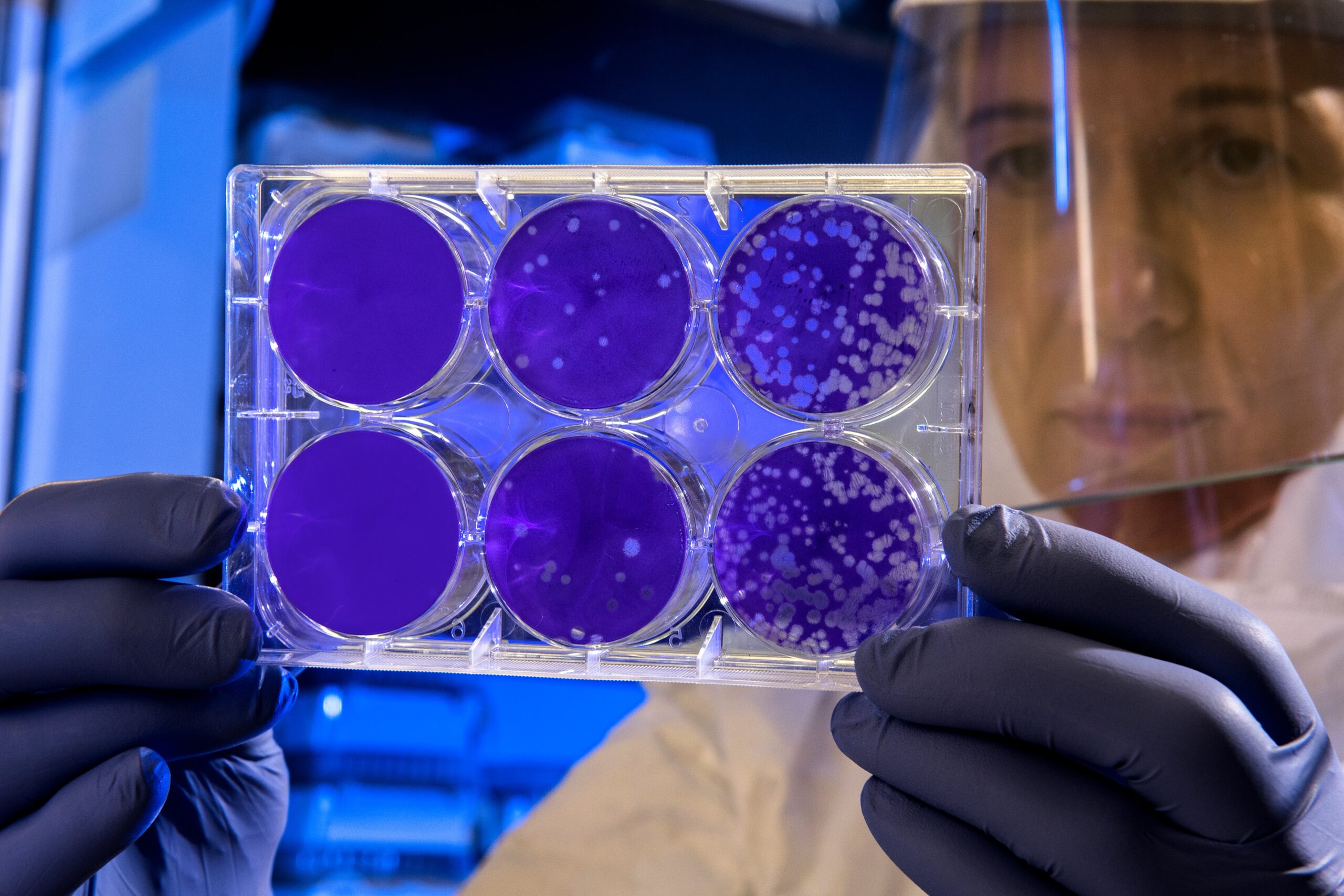

Late last week, an Oregon cannabis industry advocacy group joined two licensed businesses in filing an emergency motion to halt required testing for aspergillus, a common type of fungi, which became mandatory for cannabis products in the state beginning in March of this year.

According to a press release from the Cannabis Industry Alliance of Oregon (CIAO), “new Aspergillus testing regulations … are causing critical harm to the state’s cannabis industry and exceed the [Oregon Health Authority’s] statutory authority as there are less restrictive Aspergillus testing alternatives.” It continued, “The current testing requirements are inconsistent, confusing, and exorbitantly costly, leading to disastrous financial consequences for cannabis businesses across Oregon.”

For additional details on the situation, Cannabis Benchmarks spoke this week with Jesse Bontecou, Executive Director of the CIAO. Bontecou emphasized that aspergillus fungi, particularly some of the varieties that are now being tested for in Oregon, are environmentally ubiquitous, yet Oregon’s testing standards state that a batch of product fails if any amount at all is detected. While CIAO and the industry at large recognize that aspergillus can be a serious threat to severely immunocompromised individuals, “the justification for this level of testing is not supported by the science.” Bontecou noted that Oregon regulators have not been able to point to a single case of aspergillosis – an infection caused by aspergillus – affecting cannabis consumers.

As to the impact of the new testing regulations on licensed growers and product manufacturers, Bontecou estimated that aspergillus testing – along with newly-required screenings for heavy metals and other microbiological contaminants such as salmonella that were implemented concurrently – “probably doubled” testing costs. If a batch of product fails and undergoes remediation and retesting, costs to bring that product to market can be more than triple what they were prior to the new rules going into effect.

While remediation is an option for growers or product manufacturers who see their products fail aspergillus testing, it comes with its own set of complications. Bontecou noted that irradiating product – exposing it to gamma, x-rays, or another type of radiation – is one of the most common remediation approaches in use currently. “Whether irradiation actually impacts the quality [of flower] is unknown, but there is a perception that it does,” Bontecou said.

More research is needed to understand if and to what degree irradiation affects various qualities of cannabis flower. Anecdotally, cannabis market participants have reported irradiation affecting terpenes and shortening the shelf life of flower. Bontecou said that growers are not required to disclose that their product went through remediation, but retailers have taken to assuming that wholesale flower has been remediated if it has a failed microbiological test attached to it and are passing on purchasing such batches.

Bontecou put the cost of remediation via irradiation at between $50 and $100 per pound of flower, which is a significant portion of current wholesale prices, especially for outdoor product that has seen its spot price hover between $325 and $400 per pound this year.

Beyond increased costs for testing and remediation, growers and product manufacturers are incurring additional expenses by altering their facilities and procedures in attempts to prevent testing failures. However, given aspergillus’ ubiquity in the environment, Bontecou posed the question, “How do you fix your facility if you fail a test so that you don’t fail again?” He said that those who have seen their products fail testing are often at a loss in attempting to identify where the contamination occurred, with the possibility that it could have taken place at an entirely separate point in the supply chain. According to Bontecou, this uncertainty has even led to some cultivators – particularly outdoor growers – deciding not to plant a crop this year. They “don’t know how they can invest in an outdoor harvest if they can’t count on getting a return out of it,” he said.

Such accounts raise the possibility of significant impacts on the amount of supply in Oregon’s market if the current testing regime continues. Currently, Oregon officials have stated that the failure rate for aspergillus testing is 8%. Bontecou acknowledged that the current failure rate is not especially high, but noted that the vast majority of the flower tested for aspergillus in Oregon to this point has been grown indoors, as only harvests cut down from March 1 onward have been subject to the new rules.

Additionally, he pointed out that infused pre-rolls tested since March 1 are currently seeing an almost 17% failure rate. Given typical practices, it can be assumed that the pre-rolls in question were made largely using outdoor flower from last year’s harvest. Consequently, there’s a great deal of worry amongst outdoor growers that this year’s crops may see similar failure rates, which could be catastrophic for businesses, particularly small farms without large capital reserves that frequently get by harvest-to-harvest.

Oregon is not the only state where growers and product manufacturers are struggling with and pushing back against strict aspergillus testing. Bontecou cited Nevada and Colorado as other states where he was aware of industry efforts to challenge the justification and feasibility of such regulations. Ultimately, Bontecou painted the CIAO lawsuit in broader terms, as the legal cannabis industry “demanding and setting a standard for … regulations based on sound science – not fear-based rules.”